Automatic horizontal CNC machining center with five-axis, three-head drilling for Daily Brush Series motor cores, offering high precision, speed, and reliability.

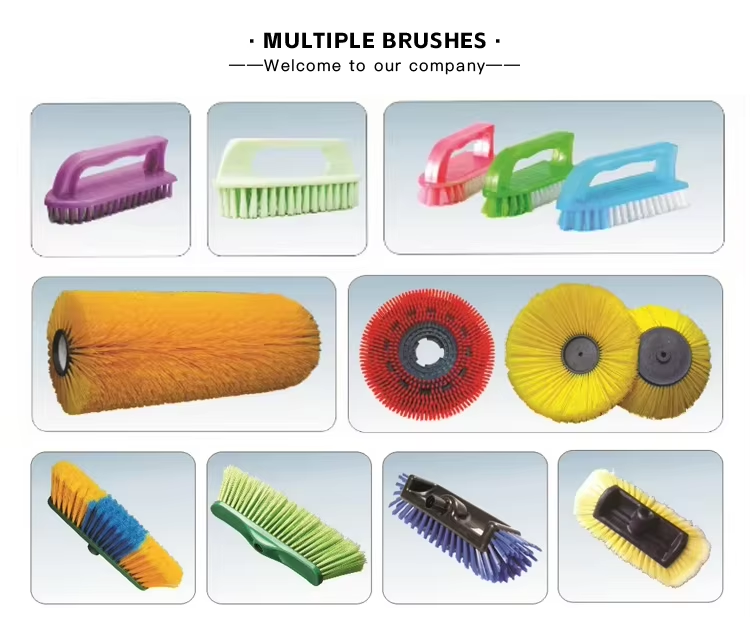

Model VM70/120/150-15B is equipped with 2 drilling heads and 1 tufting head. Its modular design easily meets the production requirements of multiple varieties and small batches. It can serve as entry-level equipment for brush manufacturing factories, and by changing the platform, it can produce products such as brooms, toilet brushes, dish brushes, and round roller brushes.

Tufting method: flat wire or round wire.

The human–machine touch screen control system, with both Chinese and English display, is flexible and easy to operate.

Capable of pre-storing up to 1,000 brush programs, and creating new programs is also very simple.

The needles, bristle knives, and all machine components are standardized in design, making replacement and maintenance very convenient.

Can produce brushes in 2–3 colors.

Different platforms can be selected to produce brushes or brooms of various types and angles.

Optional platform types include:

● Platform capable of producing sloped or vertical bristle angles.

● Platform capable of producing spherical toilet brushes and hemispherical dish brushes.

● Platform capable of producing tubular industrial brushes or comb brushes.

|

Model |

VM70-15B |

VM120-15B |

VM150-15B |

|

Axis |

5 |

5 |

5 |

|

Tufting(pcs) |

1 |

1 |

1 |

|

Driling(pcs) |

2 |

2 |

2 |

|

processing method |

Continuous production |

Continuous production |

Continuous production |

|

Stroke(mm) |

70 |

120 |

150 |

|

Speed(tufts/min) |

≤500 |

≤380 |

≤300 |

|

Filament length(mm) |

50-240 |

50-360 |

50-400 |

|

Hole diameter(mm) |

3.0-8.04.0-5.0 |

3.0-8.0 |

3.0-8.0 |

|

Power consumption(KW) |

5.6 |

6 |

6.5 |

|

Air pressure(MPa) |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

|

Weight(kg) |

2700 |

3200 |

3400 |

|

Dimensions(mm) |

2865X2365×2075 |

3075X2585×2150 |

3260X2150X2230 |

Q 1: Is your company a factory or trade company?

A: We are a factory, we are engaged in this business for more than 30 years, we also have our own trade company in charge of overseas & domestic marketing affairs.

Q 2:Do you have any certification?

A: SGS, CE, ISO, etc.

Q 3: Can you guarantee your quality?

A: Of course. We are a large scale professional factory. More importantly, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely. We can make business by Trade Assurance on Alibaba,com.

Q 4: What is the payment term?

A: The best way for both of us is 30% T/T deposit and 70% T/T balance payment before shipping, since we will test the machine before shipping. Of course, you can choose the way that you prefer more convenient payment term such as T/T, L/C, Western Union,

etc.

Q 5: How about after-sales service?

A:We can offer 12 months free warranty since the machinery arrived at your factory. We also offer spare parts or repair service to our customer anytime and anywhere, we will send our technician to your factory if necessary.

Q 6: How to reach our factory?

A: Our factory is located in Yangzhou city, Jiangsu province, China. It takes about 20 minutes from Yangzhou International Airport to our factory by car, and about 2 hours from Shanghai by train, and we will arrange our driver to pick you up at the airport or Yangzhou railway station anytime.