1.The automation transformation of the brush manufacturing industry is imperative

The following pain points exist in the manufacturing of traditional brushes (e.g. brooms, toothbrushes, industrial brushes, roller brushes, etc.):

(1)Manual operation with unstable precision and low yield rate;

(2)Production capacity can not meet the growing demand for personalization and customization;

(3)Complex manufacturing process, diverse product types, and difficult to adjust;

(4)Rising labor costs and increased factory management costs.

In this context, CNC brush manufacturing equipment came into being to help enterprises complete the leap from "manual manufacturing" to "intelligent manufacturing".

2.What is CNC brush machine? How does it work?

CNC Brush Machine (CNC Brush Machine) is a high-precision mechanical equipment that controls the process of drilling and tufting brushes through CNC technology.

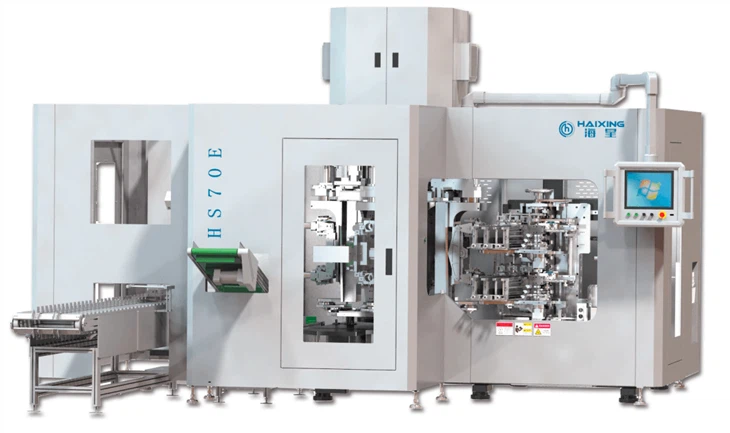

Our product line mainly includes:

Brief description of working principle:

Through CAD drawing input and software programming, the equipment executes precise positioning, drilling, tufting and other processes to realize automatic generation and batch reproduction of brush patterns. Our high-end equipment also supports multi-axis linkage and multi-station synchronized operation, which significantly improves production capacity and product consistency.

3.Why choose Starfish CNC Brush?

(1)Leading Technology Accumulation As one of the earliest enterprises in China to get involved in CNC brusher, we own many national patents, have the ability to independently research and develop software and hardware, and continue to push forward new technologies, such as the brusher technology that supports three-dimensional shaped surfaces.

(2)Strong customization ability Whether you are producing household brushes or heavy industrial brushes, we can customize the solutions and equipments according to your brush structure, production demand, hair planting materials, etc.

(3)Remote commissioning and global service We provide remote control, online training, overseas installation and after-sales service, and export to more than 40 countries and regions around the world.

4.Industry Trend: Intelligent Manufacturing and Green Sustainability

(1)Intelligent control system: future equipment will further integrate artificial intelligence algorithms to achieve automatic fault diagnosis, self-optimizing path planning and other functions.

(2)Green Manufacturing: Energy-saving motors, low-noise operation, and the use of environmentally friendly materials have become the new standard in the industry.

(3)Flexible Manufacturing: Rapid switching between different brush type production tasks has become the new demand of high-end customers.

Conclusion

The transformation of the brush manufacturing industry from traditional manual production to intelligent automation is not merely an upgrade in technology—it represents a fundamental shift toward higher efficiency, precision, and global competitiveness. As consumer expectations evolve and industrial standards rise, manufacturers can no longer rely solely on manual labor and outdated machinery to remain viable. Instead, the adoption of CNC brush manufacturing equipment marks a decisive move toward the future of smart manufacturing, where data-driven control, advanced software integration, and intelligent algorithms define productivity and quality.

Starfish CNC Brush stands at the forefront of this transformation, empowering enterprises to achieve the leap from “manual” to “intelligent” production. By combining cutting-edge CNC technology with deep industry expertise, Starfish provides comprehensive solutions that meet the diverse needs of both household and industrial brush manufacturers. From drilling and tufting to trimming and flagging, every step of the process is automated, precise, and repeatable—ensuring that each brush produced meets exacting quality standards. More importantly, Starfish’s equipment offers the flexibility to handle a wide range of brush types and materials, enabling manufacturers to quickly adapt to personalized and customized production demands.

In addition to its technological leadership, Starfish emphasizes global service and long-term customer support. Through remote commissioning, online training, and professional overseas installation, the company ensures that clients worldwide can seamlessly integrate advanced automation into their production lines. Its products are trusted in more than 40 countries, a testament to Starfish’s commitment to reliability, innovation, and customer success.

Looking ahead, the future of brush manufacturing will be defined by intelligent, green, and flexible production systems. The integration of artificial intelligence will enable equipment to self-diagnose, optimize production paths, and reduce downtime automatically. Energy-efficient motors, low-noise operation, and environmentally friendly materials will further support sustainable manufacturing practices in line with global carbon reduction goals. Moreover, flexible manufacturing systems will allow producers to switch effortlessly between various brush models, significantly enhancing responsiveness to market trends.

In summary, the modernization of the brush manufacturing industry is both an inevitable trend and an opportunity for growth. By embracing CNC automation, companies can not only improve production efficiency and product consistency but also achieve cost savings, environmental responsibility, and long-term competitiveness. Starfish CNC Brush, with its pioneering technology and forward-thinking vision, will continue to lead this transformation—helping global manufacturers build smarter, greener, and more sustainable futures in the world of brush production.

YangZhou HaiXing CNC Brush Machine Co., Ltd, founded in 1985, is a professionalcompany which engaged in research and development, manufacturing, sales and after-sale service in brush machine. After 30 years of technology accumulation with a professional team of Engineers, lots of excellent performance of the brush machines we designed and produced have been sold to domestic and foreign markets.

Hot News

Hot News